| | | Goldoni 240 Universal |  |

|

+6Charioux FLU14 vinc01 PIJO3007 chenillard77 kangelis 10 participants | |

| Auteur | Message |

|---|

kangelis

Nombre de messages : 62 Nombre de messages : 62

Age : 55

Localisation : Arta, 47100, Greece

Date d'inscription : 21/05/2013

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Mer 13 Nov 2013, 06:25 Mer 13 Nov 2013, 06:25 | |

| Goodmorning to all (Bonjour a tous !)

Thank you Mark for your kind words.

I will continue to post pictures and comments of the ongoing works in the goldoni.

Regards,

Constantinos | |

|   | | kangelis

Nombre de messages : 62 Nombre de messages : 62

Age : 55

Localisation : Arta, 47100, Greece

Date d'inscription : 21/05/2013

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Ven 15 Nov 2013, 08:07 Ven 15 Nov 2013, 08:07 | |

| | |

|   | | FLU14

Nombre de messages : 79 Nombre de messages : 79

Age : 45

Localisation : Lisieux

Date d'inscription : 05/11/2012

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Sam 14 Déc 2013, 15:56 Sam 14 Déc 2013, 15:56 | |

| Hi Kangelis, Nice to see your job on this 240. I thought it was more difficult to adapt the lombardini engine. I would like to know more details about this adaptation. Did you make a special part ? the Orange ring is a part you have made, bought, or was provided with the engine ... when you wrote "What i actually did was to replicate the dimensions of the chutch case of the old engine to the new one." I guess you drilled the clutch on the tractor to allow the threaded rods to go through this part and to be bolted on it ... or maybe it is the contrary, you drilled the orange ring. So you can easily put a slanzi or a lombardini as the clutch of the tractor has 2 sets of holes. Does your primary shaft of the gear box go inside the bearing on the picture below ?  Finally, is your engine cover is long enough ? I would say that the lombardini engine is longer than the Slanzi. NB : really lucky to find the slanzi for this price ... apparently this is a Slanzi 1550, the injectors are the model for 1550, fuel pomp & fuel filter are on the side of the injection pump & regulator. Best regards, François | |

|   | | kangelis

Nombre de messages : 62 Nombre de messages : 62

Age : 55

Localisation : Arta, 47100, Greece

Date d'inscription : 21/05/2013

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Dim 15 Déc 2013, 19:50 Dim 15 Déc 2013, 19:50 | |

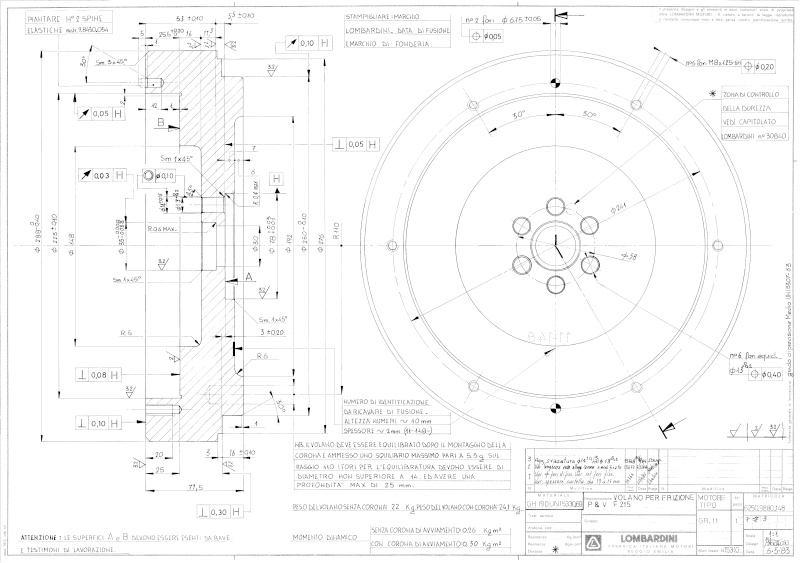

| Dear François The hole idea was to replicate the Bellhousing of the Slanzi in order to use the same clutch and the same primary shaft of the gear box. I made 2 parts. This because the flywheel of the Lombardini was flat as you can see in figure 1.  Figure 1: Flywheel of the Lombardini. The 1st one was to fit the clutch, as you can see in figure 2. I did not drilled the clutch.  Figure 2: The first homemade part to attach the clutch. The second homemade part was to adapt the engine’s bellhousing to the tractor’s bellhousing since the dimensions ware different in diameter. The Slanzi had SAE 5 bellhousing while the Lombardini had SAE 4. That means that the diameters are different. This homemade part is seen in figure 3.  Figure 3: Second homemade part. You are correct, the primary shaft of the gear box goes inside the bearing. That bearing was in the Lombardini, so I used it. Otherwise I had to made it from scratch, since the primary shaft should lie on a bearing in the flywheel (as you can see in figure 4).  Figure 4a: Bellhousing of the Lombardini.  Figure 4b: Bellhousing of the old Slanzi. As you can see from figures 4a and 4b the bellhousing are the same. I have not checked the engine cover yet. As for the other Slanzi, 1st of all it works, secondly, there are too many parts that are exactly the same in all 3 engines that I have (11Ld626/3, 1750 and 1550) !! I hope that I helped, but if you have any question please ask. Best regards, Constantinos | |

|   | | FLU14

Nombre de messages : 79 Nombre de messages : 79

Age : 45

Localisation : Lisieux

Date d'inscription : 05/11/2012

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Dim 15 Déc 2013, 22:29 Dim 15 Déc 2013, 22:29 | |

| Hi Constantinos,

Thanks for these details, I still have some questions :-) ....

When you wrote that the bellhousing are different (SAE 4 & SAE 5), these differences are only on the external/internal diameter and the shapes (round shape on the slanzi bellhousing and nearest of a square shape for the lombardini's one).

It would appear the threaded-rod position are the same, that it permits to fit directly the lombardini bell into the slanzi tractor's bell. This on this point that I have a doubt, I believed it was not possible that the positions were the same in terms of diameter and angle.

Could you indicate the height of these 2 home-made parts ?

I guess you use new threaded-rods that are longer than the original ones.

Best regards, François | |

|   | | kangelis

Nombre de messages : 62 Nombre de messages : 62

Age : 55

Localisation : Arta, 47100, Greece

Date d'inscription : 21/05/2013

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Lun 16 Déc 2013, 07:11 Lun 16 Déc 2013, 07:11 | |

| Dear François,

You are correct, the differences are on the external/internal diameter, while the shapes (round shape on the slanzi bellhousing and nearest of a square shape for the lombardini's one) aren’t of interest.

The Lombardini’s bellhousing was 1 cm shorter in diameter if I remember correct and consequently the threaded-rods diameter, while the positions in terms of angle ware the same. So, in order to fit the lombardini bell into the tractor's bell what I did was to drill down the tractor's bell.

If I remember well ( I can measure in detail when I’ll be in the garage) the height of those 2 parts was 2.6 cm for the first one and 4.0 cm for the second one. And of course I used longer threaded-rods.

Best regards,

Constantinos

| |

|   | | chenillard77

Nombre de messages : 12538 Nombre de messages : 12538

Age : 49

Localisation : seine et marne nord

Date d'inscription : 02/09/2005

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Lun 16 Déc 2013, 08:48 Lun 16 Déc 2013, 08:48 | |

| bonjour a tous !

François, pourrais tu nous faire la traduction aussi des reponses, car beaucoups sont interressés par ce post, mais ne connaissent pas l'anglais.

j'avais bien commencé, mais je n'ai pas le temps en ce moment.

merci

a+, marc | |

|   | | FLU14

Nombre de messages : 79 Nombre de messages : 79

Age : 45

Localisation : Lisieux

Date d'inscription : 05/11/2012

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Lun 16 Déc 2013, 20:29 Lun 16 Déc 2013, 20:29 | |

| Hi Constantinos, Sorry to disturb you with all my questions, but each of your answer bring a new detail I didn't see ... Maybe you have a picture of the tractor bell after you drilled it. Just to be sure, 1) you only drilled 2 holes for the lower threaded-rods ? or 2) you drilled 8 new holes at a lower position (shorter radius) but at the same angle ? If 1st way, your gear box shaft is still centered on the crankshaft ? If it's the case, I would say you are really lucky ... or I misunderstood and you did like on the second way. For the new holes (2 or 8), do the nuts are tightened against the tilted surface ? (maybe you made a special washer to get a vertical surface) NB : I thought that the rods of the lombardini bell were located on a circle for which the radius is higher than those of the slanzi but this is the opposite (Slanzi = SAE5, Lombardini = SAE4), I made the confusion due to the picture of the clutch disc, which seemed bigger than the slanzi one. Apparently, one of the rod was broken, did you change it, or maybe this one can not be used due to the bad position of the hole on the tractor bell. Not a mechanic but a scientist, you said ... I know some scientists, they are not able to change a flat tire ...  For Marc and others interested people, I will do a french summarize once all is clear in my mind  Marc, je fais un résumé dès que tout est clair de mon côté, il me restait quelques interrogations sur la cloche côté tracteur. | |

|   | | kangelis

Nombre de messages : 62 Nombre de messages : 62

Age : 55

Localisation : Arta, 47100, Greece

Date d'inscription : 21/05/2013

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Lun 16 Déc 2013, 22:38 Lun 16 Déc 2013, 22:38 | |

| Dear François, No disturb at all !!! It’s my pleasure to answer to our questions. At the end that’s we are all here, to share ideas and help each other. So, back to the point of interest !!!! The Holes on both bellhousings were in the same degrees. So, I drilled all the 8 holes just with a shorter radius. That’s because I really wanted to be sure that all will continue to be aligned in order to avoid any damage. Both parts first (figure 2) and second (figure3) needed special washers. If you do not make washers then it is possible to miss the alignment and of course the structure will not be as strong as it should. If you mean the 8th rod in Figure 2, no it was not broken, I have not tighten it yet when I took the pictures. Here are the pictures before and after the drilling in the bellhousing from the side of the tractor.  Figure 5: Before drilling.   Figure 6: After drilling. The most important thinks that I had in mind in this procedure ware: 1. The 1st homemade part should have exactly the same height with the height of the old flywheel in order to be able to use the same clutch. 2. The correct and extremely accurate alignment in both homemade parts in order to have the primary shaft perfectly aligned with the clutch and with the flywheel. 3. Moreover, I made the first homemade part and I used the bearing where the primary shaft of the gear box goes inside (as you can see in figure 4a) because I did not wanted to lighten the flywheel (maybe finally is a little bit heavier than the suggested one from Lombardini), by making a hole in the flywheel for the clutch like the one that the old flywheel (from the Slanzi) has. And this because the flywheel and the bellhousing that Lombardini suggests for 11LD626/3, when this engine to be used in Goldoni 245 Universal, is the one that you can see in the pictures below. Of course I did not replicate these 2 designs since the bellhousing is SAE5, which was not my case.  Figure 7: Suggested flywheel for use in Goldoni 245  Figure 8: Suggested Bellhousing for use in Goldoni 245 I hope that i helped a little.  I have to admit that the mechanic to whose garage I took my tractor for the engine replacement was no helpful at all (all the photos are in his garage). On the contrary the mechanic who made the two homemade parts (in the lathe) was the one that understood what I really wanted to do and he helped me a lot. The dimensions of these two parts are made with sub-micro precision. Now the tractor is in a warehouse-garage in the Department where I work. As o proof that the first one did not helped, is that I connected the clutch to the clutch pedal by my own !!! Best Regards, Constantinos | |

|   | | kangelis

Nombre de messages : 62 Nombre de messages : 62

Age : 55

Localisation : Arta, 47100, Greece

Date d'inscription : 21/05/2013

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Mar 17 Déc 2013, 21:39 Mar 17 Déc 2013, 21:39 | |

| Works been made a few weeks ago: Fixing the clutch and tires, with the help of a colleague and friend of mine.      Now I’m waiting for the holidays in order to finish with the mechanical issues which are basically: 1. To add the old or a decent hydraulic pump 2. To fix the basic electric wirings 3. And to change the engine oil, gearbox oil etc… | |

|   | | kangelis

Nombre de messages : 62 Nombre de messages : 62

Age : 55

Localisation : Arta, 47100, Greece

Date d'inscription : 21/05/2013

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Dim 29 Déc 2013, 20:29 Dim 29 Déc 2013, 20:29 | |

| Hi,

I wish you all a Happy new Year.

I have a question regarding a hydraulic pump.

I saw that Goldoni proposes (http://ricambi.goldoni.com/files/cat/univer-n/tav21260.htm#21_300) 2 pumps for the Goldoni 245 named :

22 02030045 POMPA 2P11 S and

14 02030140 POMPA 2P8,5S

What are these numbers (2P11 S and 2P8,5S)? I can't find the specifications.

Could you propose an alternative solution for these pumps?

Regards,

Constantinos | |

|   | | FLU14

Nombre de messages : 79 Nombre de messages : 79

Age : 45

Localisation : Lisieux

Date d'inscription : 05/11/2012

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Dim 29 Déc 2013, 22:36 Dim 29 Déc 2013, 22:36 | |

| Hi Constantinos, I would say that like for the 1750 engine, the pump come from the manufacturer Salami. Probably a pump group 2, the current models should be found here : http://www.salami.it/public/articoli/pdf/1591_1_E0.23.1011.02.01.pdf The best indication would be a picture of the plate where the model/type Nr is indicated. Due to the numerous combination of drive shafts (more than 10) & mounting flanges (8 models), there are other digits and letters than 2PB11S to know what model of pump you need. Maybe Salami engineers can help you as the 11LD 226 is still manufactured. Salami has a distributor in Greece  You have also few informations about the hydraulic pump fixing on the page 46 of http://service.lombardinigroup.it/documents/Manuali%20Officina/English/Work%20Shop%20Manual%20GR%2011%20matr%201-5302-296.pdf I add an other information as I checked the plate on my pump (Salami on Slanzi 1750) on the goldoni spare parts catalogue : #7 - 02030078 - POMPA 2B11 S On the plate : 2PB11.3 / S - BF1 6122 7113 1 00014 10/86 - 2 (on the aluminium body) According what I see on the salami website, features are : displacement 11,5 cm3/rev, working pressure 250 bars, min/max speed 500/3500 tr/min. "S" is for the rotation sense = Anti-clockwise. For 3000 tr/min engine speed (1500 tr/min pump speed), workflow is around 15 l/min On the website, B serie for group 2,5 and upper, for group 2 it seems to have been replaced by E serie (2PE) On page 31, you can see what is the meaning of the digits, ("how to order" section) Then, you probably will need to order the parts 4, 5, 6, 7, 8 from Lombardini [img]  [/img] Maybe part 5 is a european standard flange, you can get from your local Salami reseller. I guess that 1, 2, 3 are already installed on the engine. Happy new year also, and lot of happiness with your 240 for 2014. Best regards, François

Dernière édition par FLU14 le Lun 30 Déc 2013, 15:35, édité 2 fois | |

|   | | FLU14

Nombre de messages : 79 Nombre de messages : 79

Age : 45

Localisation : Lisieux

Date d'inscription : 05/11/2012

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Dim 29 Déc 2013, 23:29 Dim 29 Déc 2013, 23:29 | |

| Pour aider Constantinos à trouver une pompe hydraulique à adapter sur son moteur Lombardini 11LD 626-3, quelqu'un aurait-il un Goldoni 245 ?

Il faudrait avoir une photo ou les inscriptions de la plaque signalétique de la pompe Salami.

Constantinos : this is a message to ask a picture of the plate if somebody has a 245.

Did you call Goldoni ? maybe they have these informations. | |

|   | | Charioux

Nombre de messages : 875 Nombre de messages : 875

Age : 76

Localisation : auvergne, à coté de Brioude

Date d'inscription : 28/01/2008

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Lun 30 Déc 2013, 08:18 Lun 30 Déc 2013, 08:18 | |

| Et encore on s'en tire bien ce n'est pas écrit en grec!!!!! | |

|   | | kangelis

Nombre de messages : 62 Nombre de messages : 62

Age : 55

Localisation : Arta, 47100, Greece

Date d'inscription : 21/05/2013

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Jeu 30 Jan 2014, 12:52 Jeu 30 Jan 2014, 12:52 | |

| Finally i found a Hydraulic Pump !

Flowfit was very very helpful and they proposed me the following pump ( 2SPA14D10G ) that fits Lombardini:

https://www.flowfitonline.com/acatalog/Online_Catalogue_GROUP_2_HYDRAULIC_GEAR_PUMPS_534.html

| |

|   | | chenillard77

Nombre de messages : 12538 Nombre de messages : 12538

Age : 49

Localisation : seine et marne nord

Date d'inscription : 02/09/2005

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Jeu 30 Jan 2014, 13:26 Jeu 30 Jan 2014, 13:26 | |

| Hello constantinos ! you did a very good work !  I've got a lombardini engine LDA673 that I'm thinking for fitting on a goldoni in replacement of a slanzi engine. so I will study your pictures and see if there is a difference between the 11LD626-3 and the 673 clutch. I think I could have some problems with the longer of the engine? many thanks for the dimensions of your clutch adaptator ! it would be very helpfull for me. best wishes, marc salut constantinos, tu as fait un tres beau travail ! je possede un moteur lombardini LDA673, que je pense monter sur un goldoni, en remplacement du moteur slanzi. je vais etudier tes photos et croquis , et voir s'il y a des differences entre les cloches moteur du 11LD626-3 et le LDA673. je pense avoir quelques soucis concernant la longueur du moteur. je te remercie pour les plans de ta cloche d'adaptation, cela va m'aider grandement ! a+, marc | |

|   | | kangelis

Nombre de messages : 62 Nombre de messages : 62

Age : 55

Localisation : Arta, 47100, Greece

Date d'inscription : 21/05/2013

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Jeu 30 Jan 2014, 14:06 Jeu 30 Jan 2014, 14:06 | |

| Hi Marc,

Thank you !

For both (clutch and engine dimensions) it depents on what model is the Slanzi that you want to replace with the LDA673. You should adjust the dimensions that i used for the 11LD626-3, since 11LD and LDA673 propably have different flyweels.

Regards,

Constantinos | |

|   | | FLU14

Nombre de messages : 79 Nombre de messages : 79

Age : 45

Localisation : Lisieux

Date d'inscription : 05/11/2012

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Jeu 30 Jan 2014, 14:47 Jeu 30 Jan 2014, 14:47 | |

| Hi Constantinos,

Good news, you are near to get the goldoni ready for springtime.

The hydraulic pumps are not so expensive that I expected ...

I notice you choose a clockwise sense (D), is it better to connect the pipes ? be careful on where the outlet & inlet ports will be located according the position of the pipes (the big one is not really flexible)

For the ports, you choose BSP (G), I remember that my connectors on the pipes are N or T (4 holes, 3 screws are use to fix the connectors).

It should exist some adapters from N/T to BSP, but this requires additional parts.

The standard flange is the part 5 we can see on the figure 103 (on my previous post) ?

Do you need to purchase the components 1 to 8 from Lombardini ? or some of them are on the engine.

Best regards,

| |

|   | | kangelis

Nombre de messages : 62 Nombre de messages : 62

Age : 55

Localisation : Arta, 47100, Greece

Date d'inscription : 21/05/2013

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Ven 31 Jan 2014, 17:55 Ven 31 Jan 2014, 17:55 | |

| Dear François, The part No5 is the standard flange that you mention. I purchased all the parts from 1-8 from Lombardini, since the engine did not had a hydraulic pump and consequently there weren’t any parts on it. Although the pump in the link is Clockwise, I asked Flowifit to turn it to anti-clockwise. I’m aware off all that you said about the ports, I will have to use adaptors. Today I faced a major problem, at least for me. The part where the differential ends (red arrow) is broken. Opening the front CRANKCASE COVER is easy ?  Best regards, Constantinos | |

|   | | FLU14

Nombre de messages : 79 Nombre de messages : 79

Age : 45

Localisation : Lisieux

Date d'inscription : 05/11/2012

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Sam 01 Fév 2014, 14:03 Sam 01 Fév 2014, 14:03 | |

| I don't know what you mean with the broken part ... could you take a picture of it (zoom on it) ?

Is it the system to control the differential on/off ?

As I never touched this part or removed the crankase cover, I can not help you, maybe Marc know more details about this.

I remember from other posts, if you remove all the pieces of the differential, you need to be careful with the position and thickness of some washers that are used to set up the working space (clearance).

Kangelis a une pièce cassée à l'extrémité du système de contrôle du différentiel (de ce que je vois), il demande si c'est simple de démonter le couvercle, c'est à dire le demi-pont qui guide l'arbre de roue ?

Certains ayant eu des difficultés avec des GM de génération précédentes il me semble, vos avis sont bienvenus ... je peux faire la traduction, envoyez moi un MP, sinon il y a Google traduction. | |

|   | | chenillard77

Nombre de messages : 12538 Nombre de messages : 12538

Age : 49

Localisation : seine et marne nord

Date d'inscription : 02/09/2005

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Sam 01 Fév 2014, 17:40 Sam 01 Fév 2014, 17:40 | |

| Hi kangelis,

could you take a picture of the broken part?

as FLU14, I cannot see excatly what part you show.

maybe it's just a special screw where the hydraulic pipe goes, and allows to purge the circuit. if it's right, you don't have to open the crankcase.

we wait for your pictures.

bonjour kangelis,

peux tu prendre une photo de la piece cassée?

tout comme flu, je n'arrive pas a voir exactement ce que tu nous montre.

peut être que ce n'est que la piece speciale qui raccorde le tuyau d'hydraulique et permet la purge du circuit. si c'est bien ça, tu n'a pas besoin d'ouvrir la boite.

nous attendons tes photos

marc | |

|   | | kangelis

Nombre de messages : 62 Nombre de messages : 62

Age : 55

Localisation : Arta, 47100, Greece

Date d'inscription : 21/05/2013

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Sam 01 Fév 2014, 18:03 Sam 01 Fév 2014, 18:03 | |

| Hi Marc and François, I found photos from other posts where you can see the broken screw:    In my case it not only broken but it also rusted, as you can see in the photo below:  You are right, it is a special screw where the hydraulic pipe goes, and allows to purge the circuit, in order to lock the front differencial. I supose it is the No18 in the following diagram: http://ricambi.goldoni.com/files/cat/univer-v/tav15300.htm#15_340 Best Regards, Constantinos | |

|   | | FLU14

Nombre de messages : 79 Nombre de messages : 79

Age : 45

Localisation : Lisieux

Date d'inscription : 05/11/2012

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Sam 01 Fév 2014, 21:17 Sam 01 Fév 2014, 21:17 | |

| Is Hercule was the previous owner to break this screw ?

The part of this screw is probably strongly tightened ... be careful to not break the extractor (pig tail = queue de cochon)

Before to use this extractor, you can measure the internal diameter (at the bottom of the threads) on the same screw mounted on the rear differential and you can try to drill it at this diameter - 0,5. (or once the screw is removed on the back differential, try to see what size of drill goes inside the threaded hole with a little clearance)

By this way you can also check, how long is the screw and the distance you need to drill (you can put a piece of adhesive tape on the drill).

Eventually, before to drill, you can put some grease inside (maybe with a grease pump to fill entirely the hole) to avoid that the steel chippings go in the bottom of the system.

When drilling is done, you can suck up the chippings with a vacuum cleaner.

You remove the broken part with the extractor (and use penetrant oil if necessary).

One more sucking operation and then clean the grease with a special cleaning product in spray for mechanical part (a little quantity). Check with a flashlight that no chippings stay inside.

If you don't want drill, you can try penetrating oil (like WD 40) or Freezing gas (-50 °C) in spray (difficult to find) but not sure you get a good result.

*** je conseille de vérifier le diamètre de la vis à fond de filets sur la vis de raccord du différentiel arrière (ou de voir quel foret rentre dans le taraudage avec un peu de jeu), de percer la vis cassée (en ayant repéré la longueur de la vis arrière) et en ayant mis de la graisse (pompe à graisse) dans le trou pour éviter que des limailles a aillent dans le fond (piston hydraulique de commande du différentiel), d'aspirer après perçage, d'extraire le bout cassé à la queue de cochon, et de nettoyer la graisse restante au diluant / nettoyant, de vérifier que tout est propre avec une lampe torche.

Il peut essayer au dégrippant ou gaz refroidisseur mais je doute du résultat***

| |

|   | | kangelis

Nombre de messages : 62 Nombre de messages : 62

Age : 55

Localisation : Arta, 47100, Greece

Date d'inscription : 21/05/2013

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Dim 02 Fév 2014, 18:22 Dim 02 Fév 2014, 18:22 | |

| Thanks for the guidelines !!! | |

|   | | kangelis

Nombre de messages : 62 Nombre de messages : 62

Age : 55

Localisation : Arta, 47100, Greece

Date d'inscription : 21/05/2013

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  Mer 05 Fév 2014, 06:50 Mer 05 Fév 2014, 06:50 | |

| Bonjour à tous, Finally i opened the crankcases (front and rear). I have to remove these two small cylinders (with the red arrows in the photos bellow). I also found another problem. The part that controls the PTO (blue arrow) doesn't work since it is stucked! Any ideas how to overcome all these ???   | |

|   | | Contenu sponsorisé

|  Sujet: Re: Goldoni 240 Universal Sujet: Re: Goldoni 240 Universal  | |

| |

|   | | | | Goldoni 240 Universal |  |

|

Sujets similaires |  |

|

| | Permission de ce forum: | Vous ne pouvez pas répondre aux sujets dans ce forum

| |

| |

| |